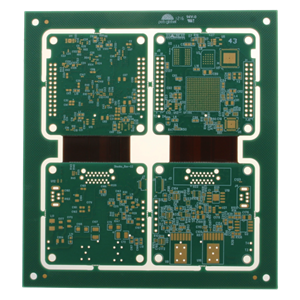

Premier Rigid-Flex PCB Manufacturer

Rigid PCBs have been around for decades, but they are not without their complications. They require a specific space to be mounted and have limited flexibility to adapt to different spaces, making them less than ideal for some applications. Fortunately, flex rigid pcb is the perfect solution for these situations. The flex rigid pcb is a combination of rigid and flexible substrates, giving the PCB dynamic adaptability and strength to meet the design requirements of any application.

To produce a high quality rigid-flex board, it is essential to choose a reliable manufacturer. A top flex rigid pcb manufacturer will offer competitive prices and a wide range of services, including prototyping, manufacturing, and assembly. They will also use advanced materials and techniques, such as HASL, OSP, and immersion gold. Lastly, the rigid-flex PCB manufacturer will be able to provide the highest level of quality and support.

Choosing the right rigid-flex PCB manufacturer is critical to ensuring that your project meets your design goals. The best rigid-flex PCB manufacturers will have an extensive portfolio of products and experience in the industry. They will be able to produce boards for a variety of applications and industries, including consumer electronics, automotive, aerospace, and medical devices. Additionally, they will use advanced technologies to create the rigid-flex PCBs, such as high-speed signal lines, power delivery and control circuits, and optical communications systems.

The Role of a Premier Rigid-Flex PCB Manufacturer

To design a rigid-flex circuit board, you need to start with a specialized PCB design software package that offers both a 3D view and a schematics view. This will allow you to see how your components fit together and will ensure that your design is accurate. Using this software will help you avoid costly errors and get your product to market faster.

Once you’ve completed your PCB design, you will need to create documentation for the fabrication process and release the file to the manufacturer. To do this, you can use the full suite of CAD features and automated drawing tools in Altium Designer (r). This comprehensive tool is included in the free trial version of the Altium 365 platform.

Rigid-flex PCBs are more complex than standard printed circuit boards, so it’s important to work with a rigid flex manufacturer that is familiar with this type of technology. Choose a company that has years of experience designing rigid-flex circuits and uses the latest technology in manufacturing and engineering.

Rigid-flex PCBs are made by laminating flexible and rigid substrates together. The rigid parts are used to carry components, while the flex substrates act as interconnection paths. The flex circuits are then drilled, plated through, and etched in much the same way as rigid PCBs. Once the holes are drilled, they’re coated with photosensitive etch resist and exposed through a mask pattern for chemical etching. The etched copper is deposited, which then receives a final finish to protect it from corrosion and environmental contaminants.